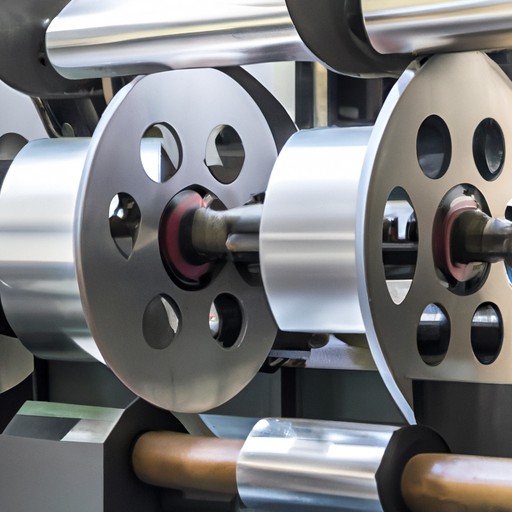

The clinging circle winding system is a revolutionary product that has been designed to provide a more efficient and effective way of winding various materials. This innovative system offers a number of unique features that set it apart from traditional winding methods, making it an ideal choice for a wide range of applications.

Another important feature of the clinging circle winding system is its versatility. This system can be used to wind a wide variety of materials, including paper, plastic, fabric, and more. This makes it an ideal choice for a range of industries, from packaging and printing to textiles and manufacturing. The system can also be easily adjusted to accommodate different material sizes and thicknesses, making it a versatile and adaptable solution for a wide range of winding needs.

In addition to its secure grip and versatility, the clinging circle winding system also offers a number of other benefits. One of the key advantages of this system is its efficiency. The clinging circles allow for faster and more efficient winding, reducing the time and labor required to complete the winding process. This can result in significant cost savings for businesses, as well as increased productivity and output.

The clinging circle winding system also offers improved safety features compared to traditional winding methods. The secure grip provided by the clinging circles helps to prevent accidents and injuries that can occur when materials become loose or slip during winding. This can help to create a safer working environment for employees, reducing the risk of workplace accidents and injuries.

Overall, the clinging circle winding system is a highly innovative and effective solution for a wide range of winding needs. Its unique features, including its secure grip, versatility, efficiency, and safety benefits, make it an ideal choice for businesses looking to improve their winding processes. Whether you are in the packaging, printing, textiles, or manufacturing industry, the clinging circle winding system offers a reliable and cost-effective solution for all your winding needs.

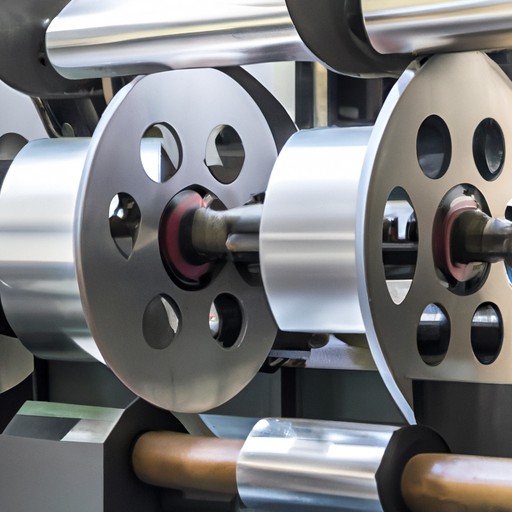

The clinging circle winding system is a revolutionary product that has been designed to provide a more efficient and effective way of winding various materials. This innovative system offers a number of unique features that set it apart from traditional winding methods, making it an ideal choice for a wide range of applications.

Another important feature of the clinging circle winding system is its versatility. This system can be used to wind a wide variety of materials, including paper, plastic, fabric, and more. This makes it an ideal choice for a range of industries, from packaging and printing to textiles and manufacturing. The system can also be easily adjusted to accommodate different material sizes and thicknesses, making it a versatile and adaptable solution for a wide range of winding needs.

In addition to its secure grip and versatility, the clinging circle winding system also offers a number of other benefits. One of the key advantages of this system is its efficiency. The clinging circles allow for faster and more efficient winding, reducing the time and labor required to complete the winding process. This can result in significant cost savings for businesses, as well as increased productivity and output.

The clinging circle winding system also offers improved safety features compared to traditional winding methods. The secure grip provided by the clinging circles helps to prevent accidents and injuries that can occur when materials become loose or slip during winding. This can help to create a safer working environment for employees, reducing the risk of workplace accidents and injuries.

Overall, the clinging circle winding system is a highly innovative and effective solution for a wide range of winding needs. Its unique features, including its secure grip, versatility, efficiency, and safety benefits, make it an ideal choice for businesses looking to improve their winding processes. Whether you are in the packaging, printing, textiles, or manufacturing industry, the clinging circle winding system offers a reliable and cost-effective solution for all your winding needs.